When you think of New York City’s skyline, you probably picture skyscrapers and iconic bridges. But tucked away at its bustling airports, a different kind of architectural marvel exists. The complexities of hangar roof construction NYC are truly astounding, involving massive clear spans, incredible load-bearing capacities, and materials built to withstand the harsh Northeastern climate. This is not just roofing; it’s a specialized field of engineering and construction that keeps the city’s aviation industry moving safely and efficiently.

Successfully completing a hangar roof construction NYC project is a monumental task. It requires a deep understanding of structural engineering, local building codes, and the unique operational needs of aviation facilities. From the initial design phase to the final installation, every decision impacts the safety, durability, and cost-effectiveness of the structure. This guide will walk you through everything you need to know about this fascinating and challenging industry.

Hangar Roof Construction NYC: At a Glance

Navigating a project as significant as hangar roof construction NYC involves many variables. This summary table provides a quick overview of the key factors you’ll encounter, from structural types to cost estimates.

| Feature | Description |

|---|---|

| Primary Roof Types | Truss Systems: Steel or wood trusses for wide spans. Arch Systems: Curved structures for self-supporting strength. Tension Fabric: Lightweight, translucent, and cost-effective. Cantilevered: Supported on one side for unobstructed door openings. |

| Common Materials | Structural Steel (A36, A572): For trusses and frames. Metal Panels (Steel, Aluminum): Durable and weather-resistant roofing. Tension Fabric (PVC, PTFE): For fabric structures. EPDM/TPO Membranes: For flat or low-slope roof sections. Insulation (Polyiso, Spray Foam): For thermal efficiency. |

| Average Cost (NYC) | $45 – $95+ per square foot. This is a general estimate; costs for a high-stakes hangar roof construction NYC project can vary dramatically based on design complexity, materials, labor, and site-specific challenges. |

| Key Considerations | Span Requirements: The distance the roof must cover without internal supports. Building Codes: Strict NYC and Port Authority regulations. Wind & Snow Loads: Must withstand severe weather. Fire Suppression: Integrated systems are mandatory. Door Systems: The roof must integrate seamlessly with massive hangar doors. |

| Project Timeline | 6 – 24+ months. Design and permitting can take several months before construction even begins. The complexity of a major hangar roof construction NYC job makes this a long-term investment. |

Why Hangar Roof Construction in NYC is a League of Its Own

Building in New York City is always a challenge, but hangar construction presents a unique set of obstacles. The sheer scale is breathtaking. We’re talking about structures that need to house everything from a Gulfstream G650 to a massive Boeing 777. The roof is the most critical component, as it must provide a vast, column-free interior space.

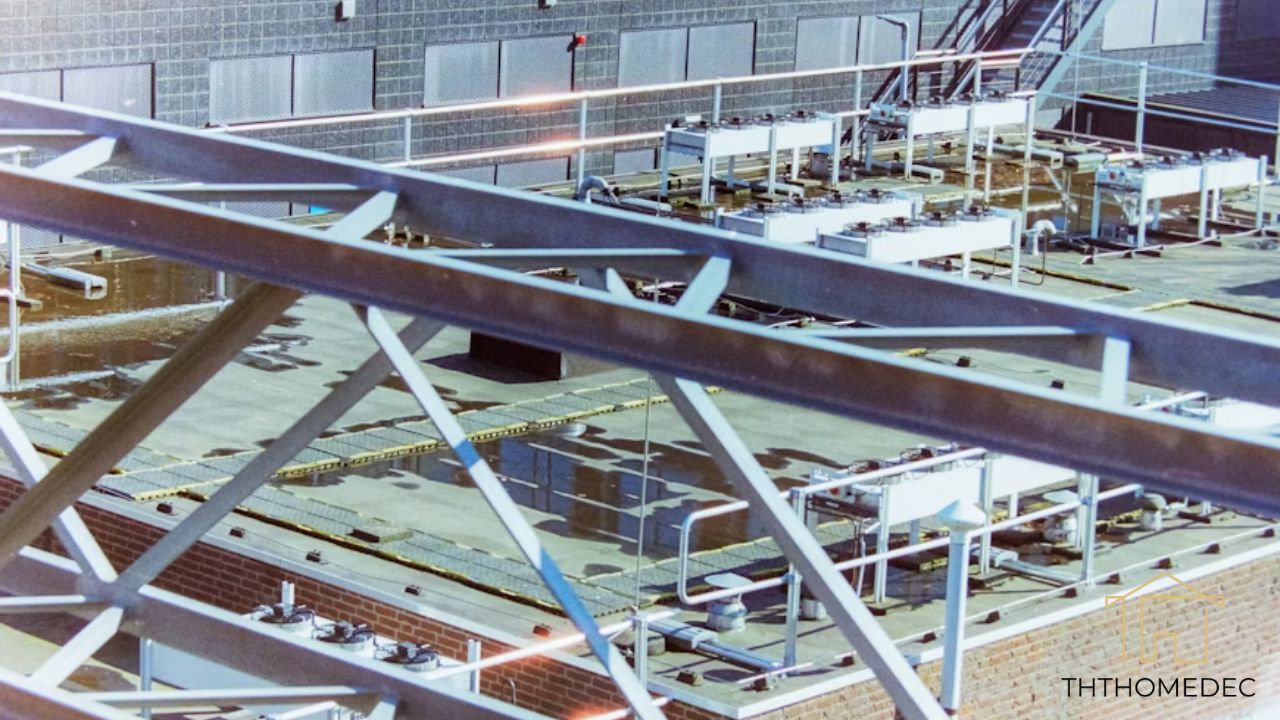

The primary challenge is the “clear span.” A hangar roof must stretch over an enormous area without any internal support columns that could obstruct aircraft movement. This requires incredible engineering feats to distribute weight and resist environmental forces. A failure in design or execution isn’t just a costly mistake; it’s a catastrophic safety risk. This is why specializing in hangar roof construction NYC is reserved for only the most experienced firms.

The Unseen Forces: Wind and Snow Loads

New York isn’t known for its gentle weather. The city experiences everything from heavy winter snowfalls to hurricane-force winds. A hangar roof, with its massive surface area, acts like a giant sail in high winds and a massive basin for snow. Engineers performing calculations for hangar roof construction NYC must account for worst-case scenarios.

They use complex models to determine the potential “uplift” from wind getting under the eaves and the “downward pressure” from accumulated snow and ice. The structure must be robust enough to handle these immense, opposing forces without buckling or failing. This meticulous planning is what ensures a hangar remains a safe haven for valuable aircraft during a fierce nor’easter.

Navigating the Maze of NYC Building Codes

If you’ve ever dealt with the NYC Department of Buildings (DOB), you know it’s a complex world. Now, add the Port Authority of New York and New Jersey (PANYNJ) and Federal Aviation Administration (FAA) regulations to the mix. A successful hangar roof construction NYC project is as much about paperwork and compliance as it is about steel and bolts.

These regulations dictate everything from fire-resistance ratings of materials to the specific requirements for integrated fire suppression systems. Sprinklers in a hangar aren’t your typical office sprinklers; they are high-volume foam or water deluge systems designed to control a jet fuel fire. The roof structure must be designed to support this heavy and intricate network of pipes and nozzles.

Exploring Hangar Roof Structures: The Core Systems

The “how” of spanning hundreds of feet without columns is where true engineering artistry shines. Several primary structural systems are used, each with its own advantages and ideal applications. Choosing the right one is a pivotal decision in any hangar roof construction NYC plan.

The Workhorse: Steel Truss Systems

Steel trusses are the most common solution for large-span hangar roofs. They are essentially a series of interconnected triangles that efficiently distribute tension and compression forces across the entire structure.

How They Work

Think of a simple bridge. The triangular shapes give it strength without needing to be a solid block of material. A hangar roof truss system works the same way but on a much grander scale. Fabricated from heavy-duty structural steel, these trusses can be designed to span hundreds of feet. They are often assembled on the ground in sections and then lifted into place by massive cranes—a truly spectacular sight during a hangar roof construction NYC project.

Pros and Cons of Steel Trusses

- Pros: Exceptionally strong, proven technology, and highly customizable for any span or shape. They also provide ample space within the truss framework to run utilities like electrical, HVAC, and fire suppression lines.

- Cons: They are incredibly heavy, requiring substantial foundational support. The fabrication and erection process is labor-intensive and demands meticulous planning and powerful equipment, which can drive up costs.

The Elegant Solution: Arch and Bowstring Roofs

Arch-style roofs offer a visually striking and structurally efficient alternative. The inherent strength of the curve allows the structure to be largely self-supporting, channeling loads down into the foundations.

Architectural and Structural Benefits

A bowstring truss, a specific type of arch design, uses a curved top chord and a straight bottom chord (like an archer’s bow). This design is remarkably efficient at handling the forces involved, often requiring less steel than a traditional parallel truss system for the same span. This can make them a cost-effective choice for a hangar roof construction NYC undertaking. The soaring, curved interior they create is not only functional but also aesthetically impressive.

The Modern Marvel: Tension Fabric Structures

A newer but increasingly popular option, tension fabric structures use a strong architectural membrane stretched over a rigid steel frame. These are not your backyard party tents; they are highly engineered systems designed for permanence and resilience.

Advantages of Fabric

- Translucency: One of the most significant benefits is natural light. The fabric allows a significant amount of daylight to filter through, dramatically reducing the need for artificial lighting during the day. This can lead to substantial long-term energy savings—a huge plus for any large-scale hangar roof construction NYC project.

- Cost and Speed: Fabric structures are often faster and less expensive to erect than traditional steel buildings. The components are manufactured off-site and assembled quickly, minimizing on-site labor and disruption.

- Durability: Modern architectural fabrics (like PVC or PTFE) are incredibly durable, resistant to UV rays, fire, and weather. They are designed to last for decades with minimal maintenance.

One user on an aviation forum, “JFK_LineTech,” shared his experience: “The new fabric hangar they put up on the north side is amazing. It feels so much brighter and more open inside. Management loves the lower electric bills. I was skeptical about a ‘tent,’ but this thing is solid as a rock. It’s handled two winters with heavy snow and didn’t even flinch.” This kind of feedback highlights the growing confidence in fabric for even demanding hangar roof construction NYC applications.

Materials That Make It Possible

The structural system is the skeleton, but the materials are the muscle and skin. The choice of materials for hangar roof construction NYC is dictated by strength, weight, durability, and cost.

The Backbone: Structural Steel

There’s a reason steel is king in large-scale construction. Its strength-to-weight ratio is unmatched. Common grades like A36 and A572 are used to fabricate the massive trusses and columns that form the hangar’s frame. Every beam and connection is precisely calculated and engineered to handle specific loads, making it the reliable foundation for any hangar roof construction NYC project.

The Shield: Roofing Panels and Membranes

The exterior roofing material is the building’s first line of defense against the elements.

- Standing Seam Metal Roofs: These are a premium choice for hangars. Panels of steel or aluminum run vertically from the ridge to the eave, with raised, interlocking seams. This design is exceptionally effective at shedding water and snow and allows for thermal expansion and contraction without compromising the weather seal. Its longevity makes it a smart investment for a critical hangar roof construction NYC job.

- EPDM and TPO Membranes: For hangars with flat or low-slope sections (often over office or support areas), single-ply membranes like EPDM (a synthetic rubber) or TPO (a thermoplastic) are used. These are rolled out and sealed at the seams to create a continuous, waterproof barrier.

The Unsung Hero: Insulation

A massive, uninsulated metal box would be an energy nightmare—scorching in the summer and freezing in the winter. Proper insulation is absolutely essential for both energy efficiency and comfort. It also helps control condensation, which can be a major issue in metal buildings.

Common choices for a hangar roof construction NYC project include rigid foam boards (polyisocyanurate), which offer high R-values, or spray foam insulation, which creates a perfect air seal by expanding to fill every crack and crevice. The energy savings from a well-insulated roof can be enormous over the life of the building.

The Financial Reality: Budgeting for Hangar Roof Construction in NYC

Let’s talk numbers. A project of this magnitude is a significant capital investment. The costs for hangar roof construction NYC can fluctuate wildly based on a host of factors, but it’s crucial to have a realistic budget from the outset.

Key Cost Drivers

- Size and Span: This is the biggest factor. The larger the clear span, the more complex and heavy the engineering, and the higher the cost. A roof for a regional jet hangar will be substantially less expensive than one for a wide-body aircraft maintenance facility.

- Structural System: A complex, long-span steel truss system will generally be more expensive than a pre-engineered fabric structure.

- Materials: Premium materials like standing seam metal roofing and high-R-value insulation cost more upfront but can pay for themselves in longevity and energy savings.

- Labor: New York City labor rates are among the highest in the nation. The skilled labor required for steel erection, crane operation, and certified roofing is a significant part of the budget.

- Site Logistics: Building at a busy airport like JFK or LaGuardia comes with immense logistical challenges. Security, restricted work hours, and limited staging areas all add complexity and cost to a hangar roof construction NYC project.

As one construction project manager noted, “Budgeting for a hangar roof in NYC is 20% materials, 40% labor, and 40% dealing with the unique hell of NYC logistics and regulations. You have to price in the complexity.” This sentiment is widely shared among professionals in the field.

A Case Study in Value: JFK’s Hangar 19

While specific financial details are often private, the redevelopment of Hangar 19 at JFK serves as a powerful example. The original structure was demolished to make way for a state-of-the-art facility capable of servicing modern aircraft. The project involved a massive new roof structure designed to meet current seismic and wind load standards, along with an advanced foam-based fire suppression system integrated directly into the roofing framework.

This wasn’t just a replacement; it was a complete upgrade. The investment in a modern, efficient, and safe roof structure directly translates to enhanced operational capability for the airline, justifying the immense cost. It underscores that a successful hangar roof construction NYC project is not about finding the cheapest option but the best long-term value.

Finding the Right Partner: Selecting a Contractor

Choosing the right contractor can make or break your project. This is not a job for a general roofer or a residential builder. You need a specialized firm with a proven track record in hangar roof construction NYC.

Essential Credentials to Look For

- Specific Experience: Ask for a portfolio of completed hangar or large-span industrial projects. Don’t just look at pictures; ask for references and details about the project’s challenges and outcomes.

- Safety Record: A stellar safety record (look for their EMR or Experience Modification Rate) is non-negotiable. This type of work is inherently dangerous, and a culture of safety is paramount.

- Financial Stability: Ensure the company is well-established and financially sound. You don’t want your contractor going out of business mid-project.

- Local Knowledge: A firm that understands the intricacies of working with the DOB, PANYNJ, and airport authorities in NYC will save you countless headaches and delays. This local expertise is vital for any hangar roof construction NYC endeavor.

User Reviews and Reputation

In the commercial construction world, formal reviews are less common than in the consumer space. Reputation is everything and is built through word-of-mouth and industry standing. However, you can gauge a firm’s quality through client testimonials and case studies on their website.

One review for a leading industrial builder stated: “Their team’s understanding of the complexities of hangar roof construction NYC was evident from day one. They anticipated permitting issues we hadn’t even thought of and managed the on-site logistics at a busy airport flawlessly. They delivered on time and on budget, which is almost unheard of.”

Ratings are often based on performance metrics like safety, schedule adherence, and budget management. A contractor who consistently scores high in these areas with major clients like airlines and airport authorities is a safe bet. It’s clear that for a major hangar roof construction NYC project, a proven history of success is the most important rating of all.

The Future of Hangar Roofs

The industry is constantly evolving. The future of hangar roof construction NYC will be shaped by innovations in materials, technology, and sustainability.

We are seeing a greater emphasis on “green” roofs, which incorporate vegetation to manage stormwater and reduce the urban heat island effect. While more complex on a sloped hangar roof, this is being explored for flatter sections. Additionally, the integration of large-scale solar panel arrays is becoming standard practice, turning these massive roofs into power generation plants.

Advancements in composite materials and computational design are allowing for even lighter and stronger structures. Drones are now used for site surveys and inspections, improving safety and efficiency. The hangar of the future will be a smart, sustainable, and resilient structure, and its roof will be the key to that vision. The ongoing need for specialized hangar roof construction NYC expertise will only grow as technology advances.

Conclusion: More Than Just a Roof

A hangar roof is far more than a simple cover. It is a marvel of specialized engineering, a critical component of aviation infrastructure, and a testament to human ingenuity. From the incredible clear spans of steel trusses to the elegant efficiency of tension fabric, these structures are designed and built to withstand immense forces and meet the strictest safety standards.

Successfully navigating a hangar roof construction NYC project requires a deep understanding of structural systems, materials, and the labyrinth of local regulations. It demands a partnership with experienced professionals who have a proven record of delivering on complex, high-stakes projects. The investment is significant, but the payoff—a safe, durable, and efficient facility that will serve the aviation industry for decades—is immeasurable. It is a vital, if often overlooked, piece of the complex machinery that keeps New York City connected to the world.

Frequently Asked Questions (FAQs)

What is the most difficult part of hangar roof construction in NYC?

Most experts would agree it’s a tie between two things: engineering the massive clear span to handle NYC’s specific wind and snow load requirements, and navigating the incredibly complex web of regulations from the NYC Department of Buildings, the Port Authority, and the FAA. The logistical challenge of building at a live, secure airport is a close third.

How long does a typical hangar roof last?

It depends on the materials, but a well-built hangar roof is designed for longevity. A standing seam metal roof can last 40-60 years or more with proper maintenance. A high-quality architectural fabric roof (PTFE) can have a design life of 30+ years. The underlying steel structure for a hangar roof construction NYC project is designed to last for the entire life of the building, often 50-100 years.

Can solar panels be installed on a hangar roof?

Absolutely. Hangar roofs provide a vast, unshaded surface area, making them ideal for large-scale solar arrays. The roof’s structural design must account for the additional weight of the panels and racking from the very beginning. Many new hangar roof construction NYC projects now incorporate solar as a standard feature to improve sustainability and offset energy costs.

Why are fire suppression systems so complex in hangars?

Because the risk is so high. A potential fire could involve massive amounts of highly flammable jet fuel. Standard water sprinklers are ineffective. Hangars require specialized high-expansion foam or water deluge systems designed to quickly smother a large fuel fire. The roof structure must be engineered to support the heavy network of pipes and the immense volume of water or foam required, making it a critical part of the hangar roof construction NYC design process.

Is a fabric hangar safe in a hurricane?

Yes. Modern tension fabric structures are not tents. They are permanent, highly engineered buildings. The fabric is tear-resistant, and the steel frame is designed to the same stringent building codes as any other structure, including requirements for wind speeds well over 100 mph. They are designed to be just as resilient as a traditional metal building.

Admin Recommendation

LWMFCrafts Inventive: A Creative Revolution in Crafting

The Enchanting World of LWMFCrafts: A Deep Dive into Paper Artistry